- Have any questions?

- +603 8724 1210

- inquiry@phesb.com

Shell & Tube Heat Exchanger

Charge Air Cooler

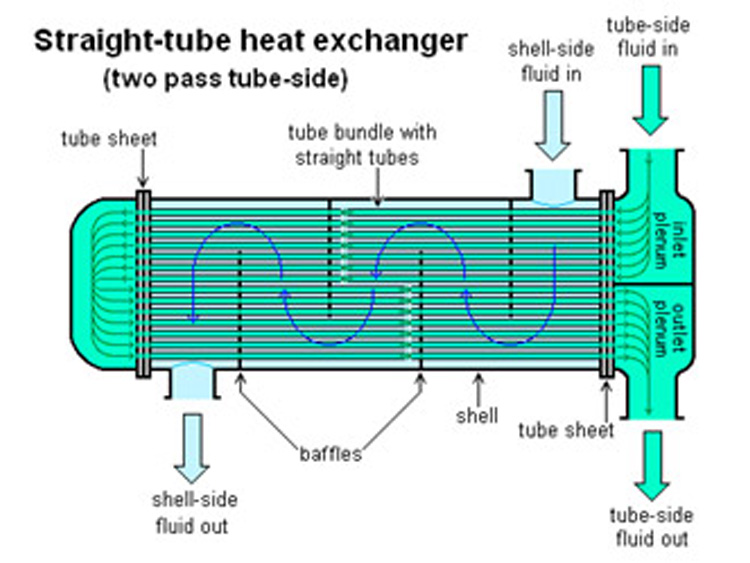

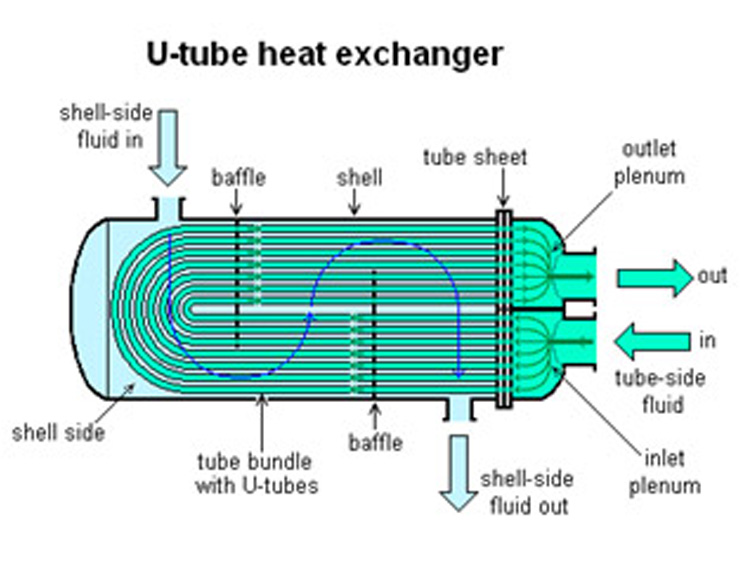

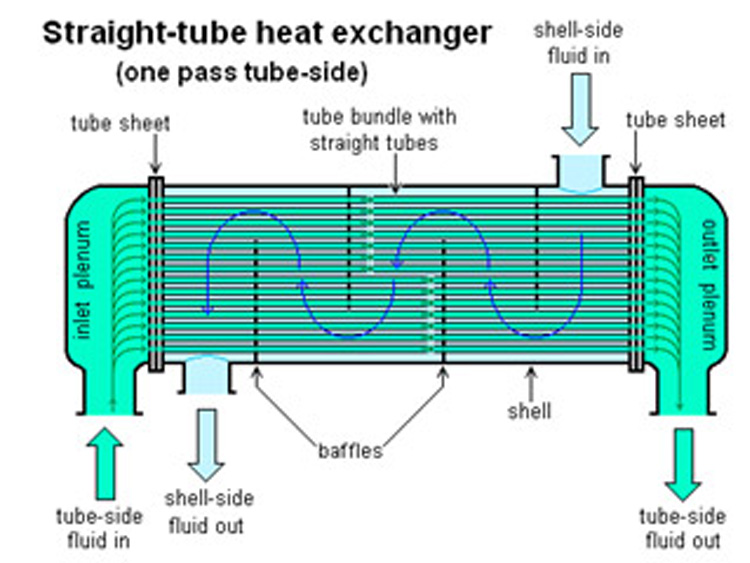

December 7, 2017Shell & Tube Heat Exchangers are used in applications where the demands from high temperatures and pressures are significant. A fluid or gas flows through the tubes while another fluid or gas flows through the shell causing heat to transfer through the tube walls. The set of tubes is called a tube bundle and may be composed of various tube configurations.

Three types of Shell & Tube Heat Exchangers: Fixed Tube sheet, U-tube and Floating Tube sheet.

The Fixed Tube sheet design consists of two stationary tube sheets attached to the shell. The bundle of straight tubes is connected between the tube sheets and contains baffles to direct the flow around the tubes in order to generate the required heat transfer. A head assembly is attached to each tube sheet

The U-tube design consists of straight length tubes bent into a U-shape with both ends terminating at the tube sheet. The tube bundle is fitted with supports or flow baffles. The tube sheet/tube bundle is placed in the shell and bolted between the head flange and body flange. A head assembly is required to direct the fluid into and out of the tube bundle. This configuration allows for the entire tube bundle to be removable.

A Floating Tube sheet design is similar to the Fixed Tube sheet design except one tube sheet is allowed to move axially within the shell while the other tube sheet is fixed. This configuration also allows for the tube bundle to be removable.