- Have any questions?

- +603 8724 1210

- inquiry@phesb.com

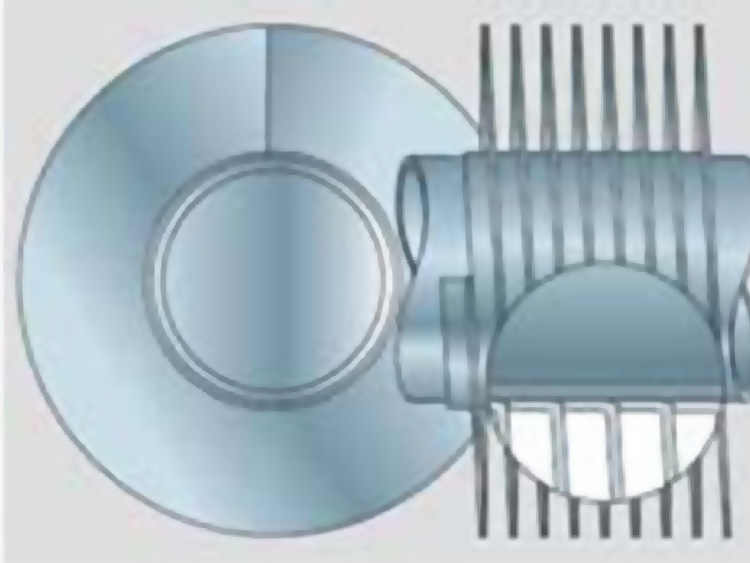

Extruded Fin

G Fin Tubes

December 7, 2017

Embedded Fin

December 7, 2017Fabrication:

The extruded fin is manufactured by compressing an aluminum bloom, or sleeve, onto the parent tube. The bloom is exposed to extremely high pressures which essentially "grows" the fins into the final fin profile. The process produces an extremely strong joint with excellent heat transfer capabilities.

Application:

Typically extruded fins are used in corrosive atmospheric conditions, such as off-shore applications. This fin design is the least economical as compared to the other fin types, primarily due to the increased amount of aluminum used (~40%) and the increased labor required to manufacture. However this increased cost can be offset if a lower grade parent tube material is used.