- Have any questions?

- +603 8724 1210

- inquiry@phesb.com

Steam / Hot Water Heating Coil

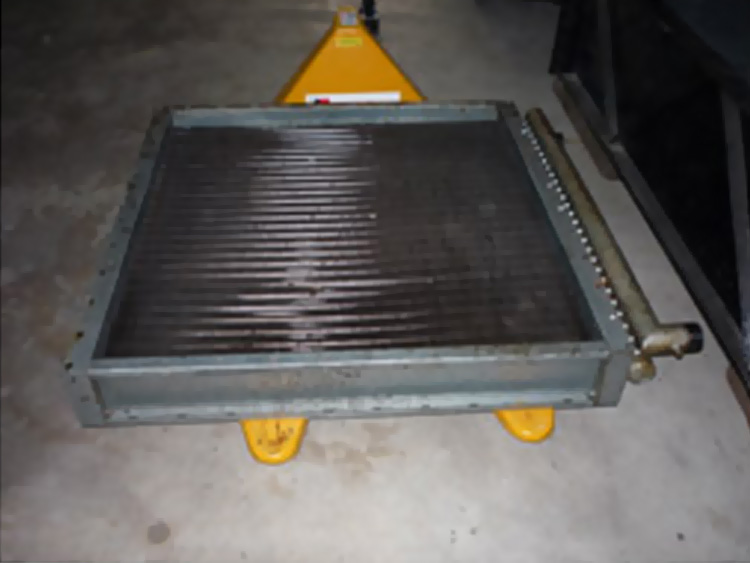

Turbine Bearing Oil Cooler

December 7, 2017

Air Cooled Heat Exchanger

December 7, 2017Standard or steam distributing construction is available for high and low pressure applications. Standard steam type is the basic 5/8" tube steam coil, known as the single tube design. The steam supply and condensate return headers and connections are normally at the opposite ends of the coil. Uniform steam distribution to each of the coil core tubes is accomplished by proper header assembly design. The steam supply connection should be located in the center of the header, with a perforated plate type baffle located directly behind this connection. Properly sized orifices are located in each of the core tube entrances into the header.

Steam distributing 5/8" tubes are the "freeze resistant" coils, known as the dual-tube design. It is important to note that any steam coil can freeze when exposed to freezing temperatures without the proper drainage of the condensate! This coil design utilizes a smaller inner tube, with precisely spaced, directional, orifice type perforations. This is to help direct condensate flow to the return header. The steam supply, condensate return headers, and connections may be fabricated as a same-end or opposite end orientation. When made as same end connected, the header appears as a single large header, but is actually two headers in one. Compartmentalizing the header serves multiple functions. As well as the supply and return, this compartmentalizing has the inner steam supply header warming the condensate return, and allows same end connected single and two row coil construction. This eliminates the unwanted core tube return bends on a steam coil.

Coils shall be designed to withstand 150 psi maximum operating pressures and a maximum steam temperature of 366°F for standard duty copper tube coils. Optional high pressure construction will include cupronickel tubes and headers to increase maximum operating pressure to 350 psi and maximum operating temperature to 450 degrees.

FINS

Coils shall be of aluminum fin type construction providing uniform support for all coil tubes. Coils are to be manufactured with die-formed aluminum, copper, with self-spacing collars which completely cover the entire tube surface. The fin thickness shall be 0.00472 +/- 5% unless otherwise specified. Manufacturer must be capable of providing self-spacing die-formed fins 8 ~ 14 fins/inch with a tolerance of +/- 4%.

TUBING

Tubing and return bends shall be constructed from UNS 12200 seamless copper conforming to ASTM B75 and ASTM B251 for standard pressure applications. High pressure construction shall use seamless 90/10 Cupronickel Alloy C70600 per ASTM B111. Stainless steel tubes shall be ASTM A249. Carbon steel tubes shall be W&D - ASTM A214 & seamless - ASTM A179. Copper tube temper shall be light annealed with a maximum grain size of 0.040 mm and a maximum hardness of Rockwell 65 on the 15T scale. Tubes are to be mechanically expanded to form an interference fit with the fin collars. Tubes shall have a nominal thickness of 0.020 inch unless otherwise specified.